Home>Products>Pulp Material Cardboard and Paper Microwave Drying>Industrial microwave conveyor oven for drying paper

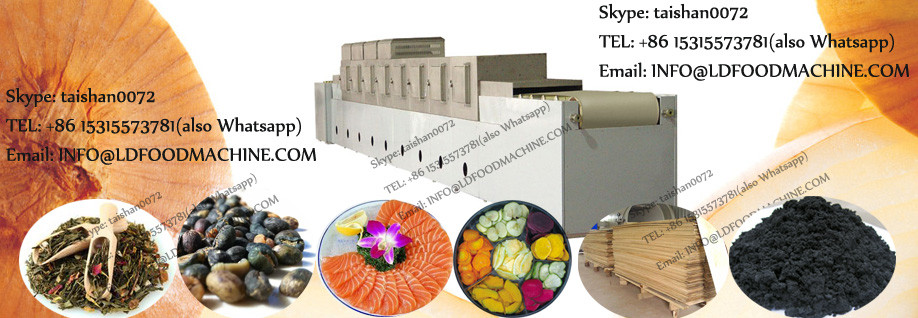

Industrial microwave conveyor oven for drying paper

- LD

Industrial microwave conveyor oven for drying paper

- Shandong, China (Mainland)

- ISO 9001, CE Certificate

- 1 Set

- US $10,000 - 20,000/ Set

- Standard Export Woodencase Suitable for Ocean Carriage

- Within 15 or 45 working days after receiveing the deposit

- 30% as deposit in advance,70% should be paid before shipment.

- 100 Set/Sets per Month

-

Potato chip production line2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Potato chip production line2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Industrial microwave conveyor oven for drying paper

Product Description

1. Application of Indstrial microwave conveyor oven for drying paper:

Mainly used in drying paper,cardboard,paper tube,paper round pipe,edge bore,gray cardboard,sheet-paper industries.Microwave drying equipment also used for drying stereotyping a variety of cardboard,gray cardboard,kraft board,cardboard boxes,paper pulp,cardboard,pulp model etc.

2.Features of microwave paper dryer:

Microwave cardboard,paper tube drying equipment,microwave drying machine,continuous industrial drying machinery for paper products,microwave paper cardboard dehydrator is a modern high-tech production equipment,it has changed the traditional heating and drying cardboard heat transfer method.Microwave don’t need preheat and heat transfer,directly heat from inside to outside at the same time.And the heating uniformity,don’t has coking phenomenon. But the traditional hot air transfer because some time low-temperature,some high temperature,resulting in different angles of coking and inside coking outside endogeny phenomenon,uneven heating.

Microwave paper products drying equipment can work continuously,easy to control,advanced craftwork,only one person can operate this machine,save labor.

Microwave have strong penetration for cardboard,practice shows that in cardboard production process, microwave drying compared with conventional process,not only fast drying speed,low power consumption,but also greatly improved the product quality.

3.Specific performance:

1. Strong glue,greatly improved water resistance and compressive strength.

2. Fast drying,cardboard uniform,flat,small change.

3. Have strong sterilizing function while in microwave drying process,greatly improved mildew resistance ability.

4. Compared with far infrared drying,drying time short two-thirds,electricity consumption save 1/3.

Microwave dring equipment used for drying 3~8cm thick wood,honeycomb corrugated cardboard,cardboard box,paper tube,wood chip,building materials,decorative gypsum board,leather etc.In the natural drying ,deformation,cracking,mildew and rot,deterioration caused material scrap is quite serious.In microwave drying ,wood utilization increase at least 5%,the outward diffusion speed of wood internal water is much larger than surface moisture evaporation speed.Therefore,the natural drying and hot air drying wood surface hardening,and affect the water spread out phenomenon doesn’t exist.Microwave drying only takes several minutes to tens of minutes,while wood in the drying process,also kill inside egg and larvae.Under the 2450MHZ microwave energy function,for example wood temeprature is 70~80 celsius degrees,only need 3 minutes can kill all the eggs and larvae.

4. Technical parameter:

5. Microwave working process:

Packaging & Shipping

While deliverying machine, microwave machine will be packed into several wooden cases or wooden pallets which willl be standard export plywood package .

Our Services

Customer Visit

Contact

Any inquiries or questions, please feel free to contact me!

Contact Us

- Potato chip production line

- AddressXinan Industry park, Jinan city, Shandong Province, China

- Phone(Working Time)86-0531-84066721

Product Categories

- Pulp Material Cardboard and Paper Microwave Drying

- Animal food machinery

- Plastic bag machine

- peanut cleaning machine

- Patty Machine

- Macaroni pasta machinery

- Potato chip production line

- Fried Pellet Snacks Processing Line

- Fast Food machines

- peanut frying machine

- Paper products drying equipment

- Pellet/Chips/3D Snacks machine

- peanut butter filling machine

- sala/crispy chips/bugle snacks processsing line

- Nutritious artifical rice food machine

- musical instruments drying

- destoner machine

- peanut half separating machine

- Vacuum Microwave

- Cracker Production Line

- Wood and Furnitures drying equipment

- instant noodle food machinery

- Corn flakes/ breakfast cereal process line

- Microwave Drying machine

- Corn Snacks Processing Line

- Seasoning Machine

- Pet Food / Fish Feed Production Line

- Denaturated Starch Processing Line

- Film blowing machine

- Floating Fish Feed Processing Line

- Soyabean protein machine

- Fried wheat flour process line

- Grains Process Machine

- Microwave Thawing and Heating Equipment

- Microwave Drying and Sterilization Equipment

- Microwave drying sterilizer machine

- Microwave Heating Thawing Machine

- Microwave Pyrolysis and Extraction equipment

- Microwave Extraction Equipment

- Microwave drying machine

- Burger Patty Machine

- ligne de traitement de croustilles

- Dog Treat/mastication alimentaire Machine

- concasseur grossier aux herbes

- Machine à Snacks pâte frite

- machine à céréale

- Rapide Machines alimentaires

- machine de découpe de viande

- machine à désosser

- Machine à frire semi-automatique

- torréfacteur commercial

- Ligne de traitement d'amidon dénaturé

- Extrudeuse à vis unique

- Machine de traitement de pâtisserie

- machine de déshuilage

- Séparateur de gravité

- stériliser à l'autoclave stérilisateur machine

- stérilisateur à micro-ondes

- Machine de formation de viande Patty

New Products

Continuous working microwave pencil board drying machine

Continuous working microwave pencil board drying machine Microwave egg tray dryer

Microwave egg tray dryer High Technology & Precision Paper Edge Board Machine U Shape Corner Edge Protector Line

High Technology & Precision Paper Edge Board Machine U Shape Corner Edge Protector Line Tunnel continuous conveyor belt type egg tray dry and sterilizing microwave machine

Tunnel continuous conveyor belt type egg tray dry and sterilizing microwave machine Cardboard microwave drying sterilization equipment

Cardboard microwave drying sterilization equipment